The only parts that make it into the mainstream are parts that can be manufactured in the tens of thousands. These large batches then require complex distribution channels and warehousing of inventory that ties up precious capital. With small-scale 3D printers, laser cutters, and CNC machines, parts can be produced at the point of sale.

When products are produced at the point of sale, the sellers never need to keep inventory and the buyers can customize their parts as needed. For instance, 3D printing may make custom ordering parts as easy as ordering a pizza in the not too distant future. Say you need a new tail light assembly for your vehicle, but you would like to customize it to include a silhouette of your favorite sports team’s logo.

In a world enhanced by 3D printers, you might start by going online to your favorite Napa or O’Reilly Auto Parts and selecting the tail light assembly based on the year, make, and model of your vehicle. You could then add your logo or other modifications from a list of options, just like you can nowadays when selecting toppings for a pizza online. Once you submit your order, your custom tail light assembly could be done and ready for pick-up in 20 minutes! In a world that utilizes 3D printers, this scenario could very easily become a reality.

One of my previous businesses was in the technical documentation industry. When desktop publishing came about, it revolutionized the industry. The complicated process of creating a user manual was gone in an instant. To create a user manual back then, you first had to write out the manual on a yellow legal pad. Next, you contacted an illustrator to draw your figures. Then you sent the pages and illustrations to a typesetter for layout. Finally, the typesetter sent the final galleys to the printer to print the final product. However, once desktop publishing came out, anyone with a computer could now be a writer, publisher, and printer.

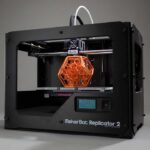

As profound as that transition was to the documentation industry, 3D printing will be to the manufacturing industry. The 3D maker revolution will transform individuals with low-cost 3D scanners, 3D printers, CNC machines, laser cutters, and free CAD software into cottage manufacturers of customized small batch products. A new industry of just-in-time custom manufacturers is springing up all over the country. These cottage manufacturers will allow consumers to simply send in an old worn out part and then the cottage manufacturers will reproduce them in small batches.

How can you be part of the new cottage manufacturing industry?