The world of the entrepreneur has been blown wide open by 3D technology. If you have an object you need to reproduce, you can use a 3D scanner to replicate it. Don’t have one? No problem! Go to your public library or another location, such as a Makers Space. Don’t want to leave the house? Use your phone to take pictures of the object from different angles. Then use a free tool like 123D Catch from Autodesk to upload the pictures and get the 3D model. Perhaps you don’t even have the object. No problem! Go online and choose from the thousands of 3D models already on the web.

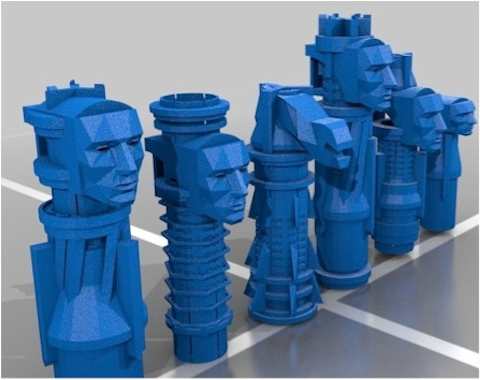

Now that you have a 3D model, you can use Computer Aided Design (CAD) software to customize the object. Perhaps you want to change the object’s color, the material, or even add a logo. Imagine creating a 3D chess set where each one of the white pieces has your face on it and each one of the black pieces has your opponent’s face on it.

Some popular 3D modeling, CAD programs, and object libraries were created as open source products, such as the ones offered by AutoCAD. In fact, these open source products are free to download and use.

Once you have created and customized the object, the CAD software will create a print file complete with internal structures for strengthening the object automatically. In fact, this software will break down the object into specific instructions based on what type of production device is used.

There are three types of production devices used to turn your 3D models into a physical object: 3D printers, laser cutters, and CNC machines. Each one of these devices uses a different method to complete the fabrication process. 3D printers use the additive process to create your 3D model. The additive process is where the 3D printer lays down layer after layer to create the object. There are also laser cutters. Laser cutters cut each slice and can even etch the surface without cutting all the way through.

Finally, there are Computerized Numerical Control machines, otherwise known as CNC machines. CNC machines use the subtractive process to create your 3D model. The subtractive process is where the CNC machine starts with a solid block of material. The CNC machine then uses a milling tool to remove layers of unwanted material little by little until your 3D model has been sculpted out of the material. Don’t have a 3D printer, laser cutter, or CNC machine to produce your new object? No problem! Take or send the file to a Makers Space and they’ll replicate it for you! You can even go online to find a 3D printing service company like Shapeways (www.shapeways.com) that will print out your design and ship it to you.

Today the entrepreneur can produce low volume products or develop prototypes through 3D printing.

How can you use the new 3D world to converts bits to atoms and produce your next idea?